- Greenhouse Gas Reduction because it reduces GHG emissions by 18% to 29% per vehicle mile traveled compared to petroleum-based fuels. Ethanol also reduces the use of gasoline and dependence on foreign powers for fossil fuels by reducing the amount of carbon monoxide and other ground level pollutants compared to gas by up to 30%.

- Positive Net Energy Balance – Corn-based ethanol has a positive net energy balance of 1.06btu per gallon for 1.00btu of energy used without ethanol by-product credits. With these credits, for things such as DDGS, corn-based ethanol has a positive net energy balance of 1.67btu per gallon for 1.00btu of energy used. Understanding the net energy gain is important because it is used in energy economics that refers to the difference between the energy expended to harvest an energy source and the amount of energy gained from that harvest.

- Biodegradable – in comparison to petroleum oil and the risk of oil spills, corn ethanol is made with organic materials. If by chance corn ethanol is spilled, 74% of it will be broken down within 5 days.

- Usable By-Products – The two chief by-products of corn-based ethanol are CO2 and DDGS (Distiller’s dried grains with solubles: the nutrient rich co-product of dry-milled ethanol production) both of which are usable in other industries. The CO2 can be captured for use in the food and beverage industry. DDGS can be used for cattle feed or even further crushed to extract corn oil for food or biodiesel production uses.

- Most Infrastructure In-place – Most cars in the U.S. are Flex Fuel capable therefore it can be used by all vehicles that use gasoline in the United States at concentrations of up to 10% ethanol. With few alterations, vehicles can also be converted to E85 concentration of ethanol.

- Economically Beneficial: It is inexpensive to produce and increases the amount of jobs in the economy.

This chart represents the mean ‘Greenhouse Gas Emissions’ for each type of respective vehicle on the market, and the associated fuel types each of these vehicles is able to operate on. In all vehicles which are able to use Corn Ethanol fuel products, such as E85 (85% ethanol and 15% gasoline), their respective emission rates were far lower than that compared to petroleum gasoline or natural gas.

This chart represents the life cycle of all greenhouse gasses produced in the United States as a percentage of petroleum products. Petroleum products emissions are the highest, due to them being the 100% level for all other fuel sources to be compared to. Switchgrass ethanol is the lowest at roughly the -10% emission level, while corn ethanol produces roughly 78% of the emissions of petroleum products.

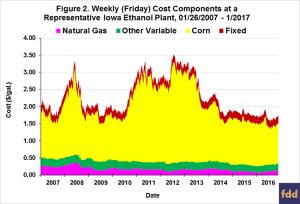

Based off of a representative Iowa ethanol producing plant (profitability):

- Dry mill plant constructed in 2007

- 100 million gallon annual ethanol production capacity

- Plant construction costs of $2.11 per gallon of ethanol production capacity

- 40% debt and 60% equity financing

- 8.25% interest on 10-year loan for debt financing

- A total of $0.21 fixed costs per gallon of ethanol produced

- Non-corn, non-natural gas variable costs (including denaturant) of $0.21-$0.26 per gallon in 2007-2011

- Non-corn, non-natural gas variable costs excluding denaturant of $0.16 -$0.17 per gallon after 2011

- Variable denaturant costs after 2011 computed as 2 percent of wholesale CBOB price

- 30 cubic feet of natural gas per gallon of ethanol

- 2.80 gallons of ethanol (including denaturant) produced per bushel of n of ethanol and $4 per ton of corn processed

- 16 pounds of dried distillers grain (DDGS) produced per bushel of corn processed

- 0.55 pounds of corn oil per bushel of corn processed (starting in January 2012)

- Netback (marketing) costs of $0.05 per galloModel based upon Representative Iowa Ethanol Plant to track profitability of ethanol

Profit of ethanol production based off of representative Iowa plant:

Four major cost components of producing ethanol on a large scale: