Now that we know both sides to the conversation of what corn ethanol is and its environmental impacts, we can come to a conclusion on whether or not we should use it as our main fuel source. to come to a final decision we must consider the economical, agricultural and environmental externalities that can occur if we were to implement corn ethanol as the main fuel source for a America.

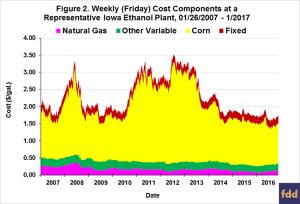

Economics: In 2006 there was a rapid increase in the price of corn due to the increased production of corn ethanol. During this time, there was an ethanol mandate to implement more ethanol into our fuel economy. However, the extent to which higher corn prices are caused by ethanol subsidies is hard to calculate. The crop yield in 2006 was not as much as they expected which also contributed to higher prices in the corn market. To put the cost margin in perspective, if you were to invest in a 100-million gallon ethanol plant, that would cost 125 million dollars. In the summer of 2005 the plant could have been paid for in a single year due to the increase demand of ethanol as an additive and the growing gas prices as well.

Agricultural/Environmental Externalities: To convert our main fuel source to corn ethanol, we must look at the environmental impacts that may occur in the process of growing corn and the actual distillation and fermentation of the biomass, turning it into ethanol. Using corn ethanol as an additive decreased greenhouse emissions by 18% to 29% per vehicle mile traveled in comparison to petroleum-based fuels. It may emit less greenhouse gases, but it also doesn’t produce as much energy as gasoline does. Researchers at University Press of Colorado also noted that corn causes serious soil erosion at rates amounting up to 18 times faster than the rate of soil formation. Using corn ethanol in our current engines is possible if we use it as an additive at a 10% concentration. If we were to solely use ethanol gasoline in our engines we would have to account that ethanol gasoline is corrosive to steel. We would have to restructure our piping systems or completely change our engine system which has the potential to become a very expensive endeavor.

Conclusion: Now that we have looked at both sides of the argument on whether or not we should use corn ethanol as our source of fuel, we can come to a decision. Using corn ethanol as our main fuel source is not practical and would be to expensive to implement. The agricultural detriments that come with farming corn as well would add to the problem of soil erosion as well. The better alternative to implementing corn ethanol is to make it an additive to all of the gasoline we pump in our cars so that it can decrease the demand for gasoline and emit fewer greenhouse gases.